Compost bin manufacture

Practical Action

Material required and cost for fabricating one concrete bin

Description

Amount /rate

Cost (Rs)

as prices on 1/06/2005

Cement (rapid hardening

(Cost -18000.00/mould)

300.00

cement)

30.0 Kg

112.50

Iron (1/4” rods)

1.25 Kg

60.00

Metals(3/4”)

1.5 cu ft

50.00

Sand

1.25 cu ft

60.00

Paints

3 bins/person/day

275.00

Labour

Assuming 100 bins are

180.00

Cost for mould

produced from 1 mould

Total

1037.50

Fabricating process

A) Preparation of the concrete mixture

Material

Sand

Metal

Cement

Ratios

4 pans (screened through ½” mesh)

3 pans (size ¾”)

30 kg

The materials above should be well mixed and then gradually add water to have a free-flowing

concrete mixture. A good finish can be expected by adding 1 pan of quarry dust.

B) Bottom pad

Steps

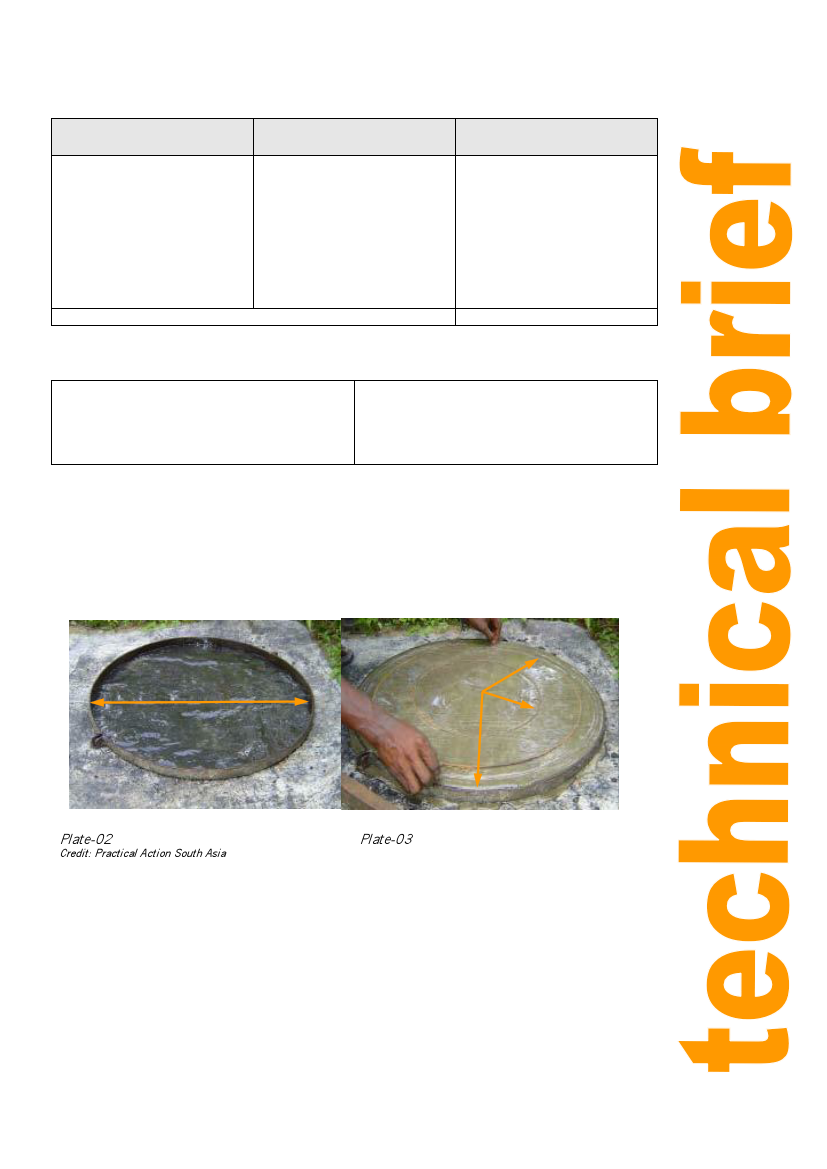

1. Get the bottom pad mould (1” width iron ring that is bolted by one side) and place it on a

polythene sheet laid on levelled ground (Plate-02).

2. Pour concrete mixture into the mould (half –fill).

20”

26”

25” 14”

Plate-02

Credit: Practical Action South Asia

Plate-03

3. Place iron rings (¼”) as in diagram (three rings) Plate-03.

4. Fill the mould with concrete mixture covering the iron rings completely.

5. Level the surface using a straight pole and remove the excess concrete from the mould

(maintain thickness 1”).

6. Locate 4-5 PVC pipe pieces (½ ” diameter and 2” long each) to make the pad porous (Plate -

04).

2